How is a flyrod from Beaverhead Rods different?

A simple explanation is just not possible ... there is a somewhat uncommon synergy that occurs when the specific design elements of this rod come together. Some people think it's a strange black magic of sorts. I think it's just a little more of a pre-determined physics result, that luckily, seems to be more repeatable, than traditional rods of the past. The cumulative result is the production of a very efficient (fast, light, strong) fishing tool. We need to adjust our thinking at this point,...Hiram Leonard, Jim Payne, E.C. Powell, and Lew Stoner were all looking for this rod in their day. Composites technology didn't exist at that time so it was virtually impossible to discover, or especially, to build it. The clock has been ticking since those days and the cutting edge of physics in our "new time" is now just becoming realized in the progression of bamboo rods.

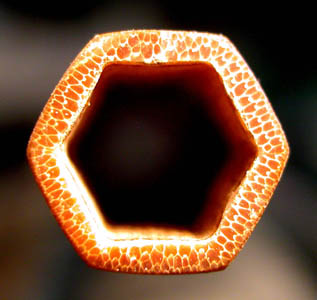

The all important blank for these rods starts differently than all other bamboo rods. The culm is acoustically profiled to assess its' fiber to pith ratio, and consequently its' ability to transfer energy, and withstand both tensile and compressive stresses. Throughout the entire process of building the rod these assessments and matching techniques take place, even in the matching of finished tips and butts. As the saying goes "there is no such thing as a bad material, just a bad application".When one thinks about it with reference to Powell, or Stoner, in their day and age, they were faced with the same quandry.Why replicate a Garrison from the past containing oblolete design with respect to their times? Indeed, they did not copy anyone, much to their credit, they were perceptive enough to know that time itself, and knowledge, had already moved on. I strongly doubt that we could accept Ferrari replicating Ford model "Ts". (why in the hell would they?)

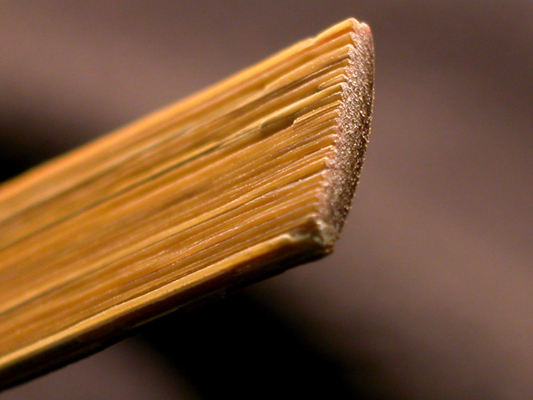

The individual strips 0f these rods receive a specific treatment depending upon their fiber density which enables them to become more structurally sound in their own right, before final bonding. This proprietary treatment renders them more resistant to the compressive and lateral fiber buckling stresses which plague traditionally built bamboo rods (glass and graphite as well as a matter of fact). Since I came from fifteen-plus years in the snowboard/composites industry, you might want to think "monocoque strength" in each individual strip before they even begin to be considered for the specialized epoxy/molding process. Porsche, is doing this now in this years new production Carrera GT, a complete carbon fiber monocoque chassis weighing 175 lbs. It quite obviously works, and has for years in high end auto racing. in short it's "damn strong construction".

The difficulties and parameters of the gluing process for these blanks have a tendency to make many people in product manufacturing run for cover. Toxicity runs very high and precautions have to be taken. Simply handling the materials properly places one in a "zen like, robotic" state of mind, time, and space. Not even the most miniscule mistake with respect to out-gassing, barometric pressure, temperature, humidity, mixing, handling, and the specialized vacuum cure sequence necessary is allowable. No time and temperature variations can exist even during the 2nd and 3rd cure phases because of tensile or compressive requirements in the final cross linking of the adhesive. Gluing has to be done absolutely perfectly each time. Mistakes are completely Taboo!

To enhance the power transference and match the lightness of the rods a specifically designed proprietary carbon fiber "hinge free," ferrule system is incorporated, again using snowboard /composites technology. It provides a substantially more sensitive feel and greater positive control than traditional metal ferrules with one twelfth the weight. User un-friendly ferrules are now a thing of the past. The "I'm swinging a small potato in the middle of my rod feeling" is also gone! And since the ferrule eliminates "hinging", energy transference from butt to tip is more "purely" established with less energy loss overall.

Utilizing "cutting edge" design parameters and a constant focus around two main criteria, strength and light weight, practically no stone was left unturned in the quest for the "Faster, Lighter, Stronger," bamboo rod. The overall and specific physics of what makes a flyrod do its' job were evaluated many times with each new variable uncovered. My friends, Glenn Brackett, Jeff Walker, & Jerry Kustich, down the alley at the RL Winston bamboo shop kept bringing up the old adage "How hard do you want to make it?". Guess what, sage advice, their time proven awareness of building bamboo rods in a production manner was completely correct. I had to keep at least some sensibility of affordability and production in sight. (click here for photo)

Guide spacing's were altered because of the inertial load they contributed to the rod. Snake Brand Guides were chosen because of their light weight and ease of use (no filing or prepping).The tiptops are shortened 100 thousandths of an inch however to reduce rod tip weight at its' outermost important point (extreme?, possibly, but with a purpose).The length of wraps was adjusted to allow for a more productionized coating of the wraps without allowing an unacceptably higher "swing weight" to ensue. The finish reduces weight by being auto clear coat sprayed on to insure a thin, even, almost bulletproof lightweight coating. Production time became critical in the scope of the "big picture" of things which are uniquely human, as I enjoy my time spent fishing, because after all, that's still supposedly what it's all about. There is a good story about the late, and great, Gary Howells being interviewed one time. The interviewer asked how many rods do you make per year, to which Howells replied, the question should be, how many days do you fish each year?

Hardware was a serious weight concern, nickel silver was completely out because of its' boat anchor characteristics. Aluminum, being about seven times lighter was rather obviously the only way to go. Even then a slim design was chosen to further eliminate excess weight. The seat spacer was a particularly difficult concern. Coco bola, rosewood, walnut, fiddleback maple, etc. have all been used to excess and they're somewhat heavy. Outside my shop was an old gnarled golden willow, (shortened by the power company through the years). Discovering that 30 lbs. of burl yielded less than a pound of useable reel seat wood (theoretically increasing its' inherant value,) prompted me to learn to stabilize it, and use it (I know, making it hard again). But, it wasn't boring due to over use, and it was extremely lightweight, if not fascinatingly beautiful with respect to its' grain and color. (click here for photo)

Cosmetics come at the end of the list of main concerns because frankly "Frills are for Sissies" and Performance..., "Absolutely Rules". The winding check and butt cap are made of cherry, stabilized, and finally along with the willow spacer coated with auto clear coat, a thin protective coat, not meant to fill nuances in a plasticizing manner, but to accentuate the three dimensional quality of the burl. An attempt to seal the wood from the elements and yet to celebrate the small fissures, and knots, and bring attention to what nature wanted us all to notice about her own handiwork. Clean, simple, and efficient, is still quite apparently, the inviolable best.

When it's all said and done a rod that's " Faster, Lighter, and Stronger" with outstanding fishability emerges, one which can stand alone in the bamboo flyrod world based upon its' own merit. The first built for truly hardcore long days of "Combat Fishing", rain or shine, windy or calm. A totally no "Bull", no nonsense approach to using the time we have left for better experiences through better fishing efficiency (I can't teach you to fish more effectively, but, I can build you a good tool which can certainly help). Now there are no excuses left when natures clock announces the time, it's still fishing time. In fact when you do a wet cast of forty feet and have the line speed to dry the fly on the back cast with no false casting your fishing effectiveness just increased over 50%, and we all know the old saying about not being able to catch anything unless the hook's in the water. Now your on Montana and natures natural time clock, and "Winning the Game"!

©2005Beaverhead Rods LLC. - Site design and maintenance - Wayne Maca